Printing unique tools and equipment, creating new product designs, and manufacturing a large range of diverse objects are all possible with 3D printing technology. On the other hand, 3D printing can produce substantial amounts of waste despite the power of this technology and the advantages it holds over other traditional manufacturing techniques.

It is such a relief to know that there are printing strategies you can employ to minimize the production of 3D printing waste without putting the environment into compromise.

You can learn below about the various 3D printing strategies that can reduce waste and thus make your 3-dimensional printing processes more eco-friendly.

3D Printing in the Australian Sector: How Does It Create Pollution?

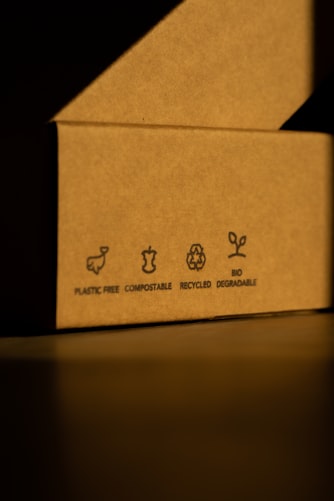

Although certain 3D printing filaments are biodegradable, others in use today, such as ABS, PET, and nylon, are not. If these additive manufacturing filaments are not recycled, they will end up in landfills. They will add to the currently worsening pollution of the environment.

Obsolete prototypes hastily produced 3D objects, and failed 3D prints will add up to the already overwhelming amount of garbage we dump every day if we don’t come up with measures that will repurpose them.

Unfortunately, almost every biodegradable filament used in 3-dimensional printing will not degrade on its own or right away unless certain conditions are met. For example, PLA filament, the most prevalent material in additive manufacturing, is biodegradable but will not break down if simply left outside. It needs a certain amount of humidity, temperature level, as well as the presence of specific bacteria, to break down.

Depending on the material used, 3D printed objects made with biodegradable filament can still contribute to pollution if they are not recycled.

Avoiding 3-Dimensional Printing Waste

From the very start, only use sustainable filaments in your additive manufacturing work. While the cheapest or most flexible option is not usually the most ecologically sound, there are sustainable options available to help make your printing more eco-friendly. This includes the hemp-derived filaments, which most of the time contain only biodegradable components.

With these biodegradable filaments, one-off items can be prototyped or experimented with without worrying about the plastic and where its ultimate end will be.

But not all projects call for entirely biodegradable filaments. Even in these situations, you can employ more ecologically sound filaments. If the additive manufacturing filaments offered are suitable for your project, they can be a great way to reduce resource usage and make 3D printing more sustainable. In other situations, the recycling process uses only renewable energy, making the filament even more eco-friendly.

Additionally, you can employ other waste-minimizing techniques — such as powering your 3-dimensional printing work with renewable energy sources whenever possible, and water-based paints — to mitigate waste or any kind of pollution likely to be generated by your printing.

Alleviating 3D Printing-Related Pollution

While 3D printing is a powerful tool, in the absence of proper precautions, it may be harmful to the environment if not used properly. The equipment consumes a lot of energy, and if it is not powered by renewable energy, it will increase your carbon footprint. The object that is 3D printed with the wrong filaments — even those labeled as biodegradable — will not decompose and runs the risk of piling up in the environment.

The good thing to know is that there are proven solutions that can help mitigate the pollution that 3D printing generates. For instance, you can employ specialized filaments to create objects that are completely biodegradable or convert them to renewable energy to aid in limiting the production of waste materials.